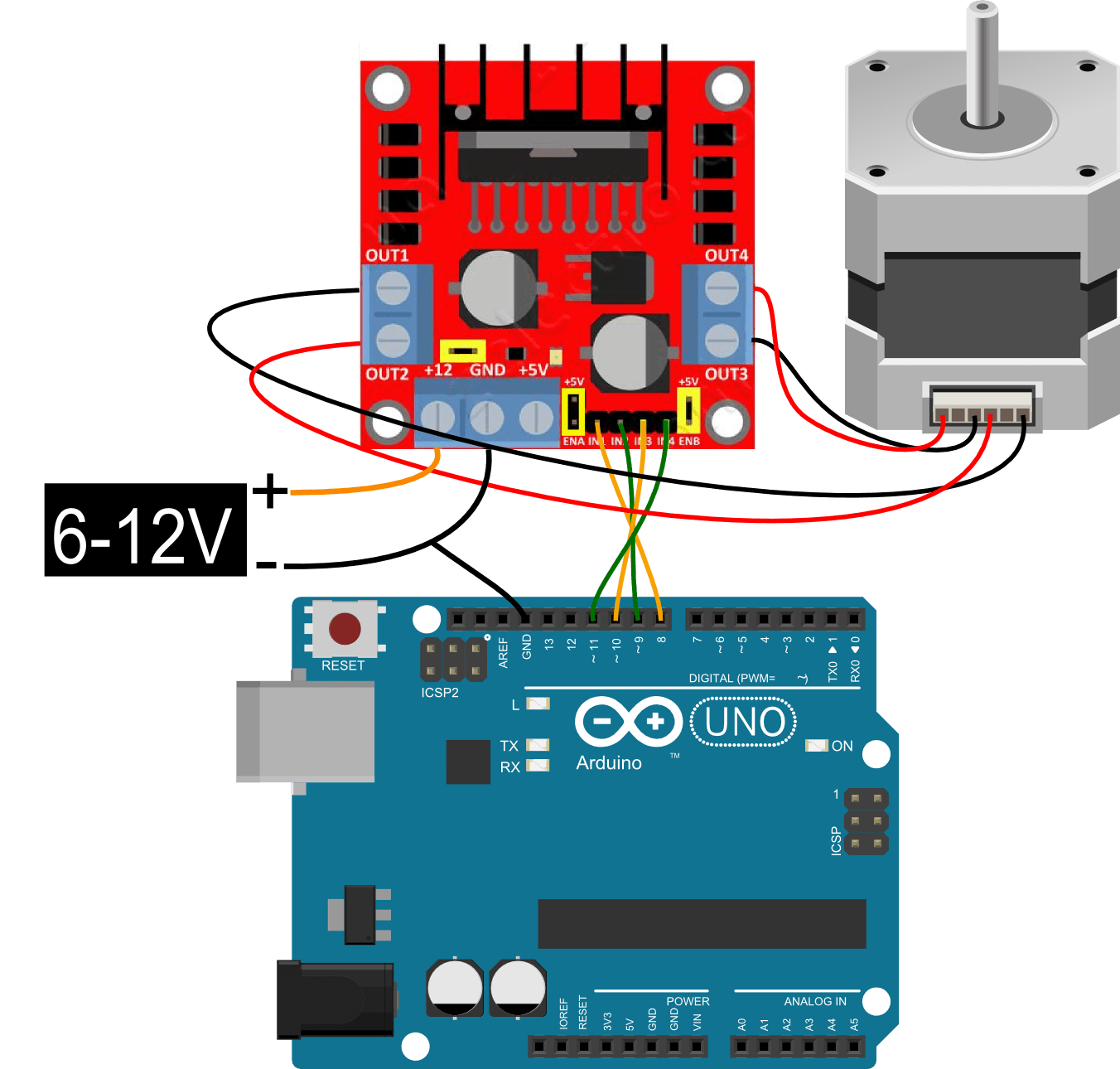

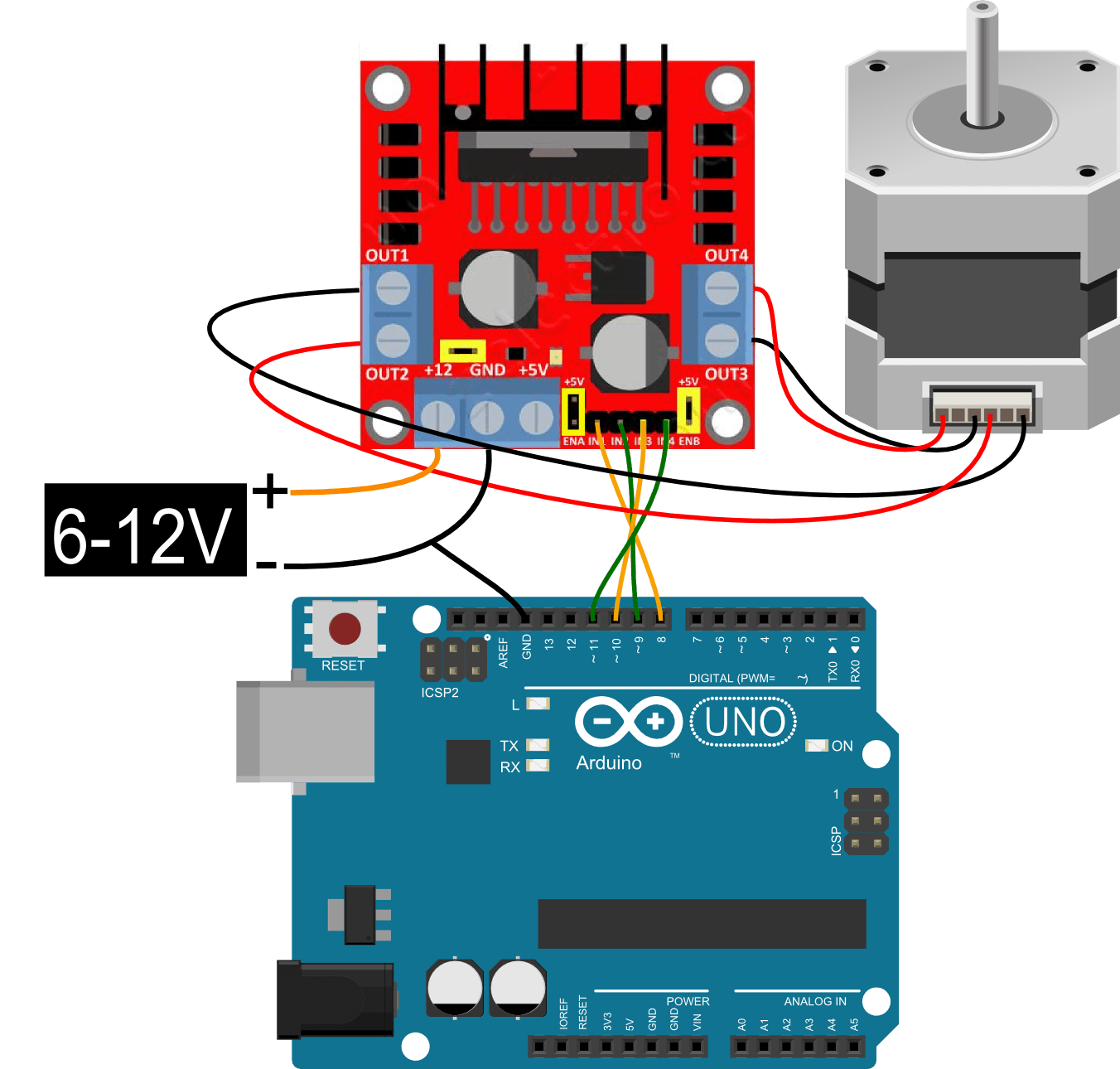

I am using the driver as per website:

https://coeleveld.com/arduino-stepper-l298n/

With the code on this page everything works fine. I can not force this IC to work with B4R.

I looked at the library Stepper.cpp - Stepper library for Wiring/Arduino - Version 1.1.0 and it should be simple, but help always will be useful: D

https://coeleveld.com/arduino-stepper-l298n/

With the code on this page everything works fine. I can not force this IC to work with B4R.

B4X:

/*

Stepper Motor Control - one revolution

This program drives a unipolar or bipolar stepper motor.

The motor is attached to digital pins 8 - 11 of the Arduino.

The motor should revolve one revolution in one direction, then

one revolution in the other direction.

Created 11 Mar. 2007

Modified 30 Nov. 2009

by Tom Igoe

*/

#include <Stepper.h>

const int stepsPerRevolution = 200; // change this to fit the number of steps per revolution

// for your motor

// initialize the stepper library on pins 8 through 11:

Stepper myStepper(stepsPerRevolution, 8, 9, 10, 11);

void setup() {

// set the speed at 60 rpm:

myStepper.setSpeed(60);

// initialize the serial port:

Serial.begin(9600);

}

void loop() {

// step one revolution in one direction:

Serial.println("clockwise");

myStepper.step(stepsPerRevolution);

delay(500);

// step one revolution in the other direction:

Serial.println("counterclockwise");

myStepper.step(-stepsPerRevolution);

delay(500);

}I looked at the library Stepper.cpp - Stepper library for Wiring/Arduino - Version 1.1.0 and it should be simple, but help always will be useful: D

Last edited: